Dust Extraction for the Fossil Preparation Workshop

Dust extraction of stone and abrasive dusts has been a bit of a 'dark art' for some time. In this article, we will cover some of the options available for the home workshop. As fossil preparators, there is no guidance out there that specifically applies to us. However, there is a great deal of guidance for stonemasons and industries that are exposed to stone dust like construction and stonemasonry. Dust extraction is more commonly known as 'Local Exhaust Ventilation' or LEV in industrial circles, so if you are looking for further advice or country specific guidance and/or regulations, this is the term to search for.

We'll do our best to be informative, and not dry and 'dusty'. There's nothing worse than reading a 'sucky' article about extraction. Anyway, puns over... we hope that this article brings you 'suck-sess' in setting up your workshops safely and correctly.

Below we will cover the different types of dust extraction. We are referencing a number of UK models as that is where we are based, but have provided both metric and imperial conversions where possible in order to allow people worldwide to benefit from this article. If you understand the principles of what we are discussing, and are able to work out what would suit your workshop, you can search for similar specifications wherever you are in the world.

Many amateur fossil preparators don't use dust extraction when they are only using air scribes or air pens in their home workshop for maybe a few hours a week, but dust control becomes essential if you are using air abrasives or working long hours in your workshop on a frequent basis. To a reasonable extent, if your face mask is well fitting with suitable filtration, you'll find that you can control the air that you are directly breathing quite well to make sure that it is free of the fine dusts that are so dangerous.

If you're unsure why you might need dust extraction in your home workshop, or why certain dusts created in fossil prep might be a health hazard, have a read of our health and safety article.

Here are a number of different choices we have seen people using in their home workshops. Anything in the red box (to the left) should NOT be used in the home workshop. Unfortunately, these lull the operator into a false sense of security as they remove the nuisance dust reasonably effectively, but the filters are not able to remove respirable silica from the air as it is too fine. Therefore they are potentially more dangerous than no dust extraction at all, forceably pumping respirable silica around your workshop.

In the blue box (top right) are a couple of options that we have in our online shop. As they are, they would fall into the 'red' category, but they can be modified to vent the dust outside into the atmosphere instead of into the dust collection bag. We will talk you through how to do this, further down in this article.

In the yellow box (bottom right) are two types of extraction you can use with zero modification. These are vacuum extractors with HEPA filters, meaning that they clean the extracted air extremely effectively before pumping it back into the room. Pictured here are the BOFA DP400 and an H-Class vacuum. H-Class means the highest level of filtration, conforming to an industrial standard. The air recirculates back into the room, with more than 99% of airborne contaminents removed. You can also purchase H-Class vacuums with filter shakers which help keep the filter free of clogs.

DUST CONTROL

There are two main types of dust extraction; ones that vent dust outside, and the enclosed types that filter the air that is returned to your workshop. No dust extraction is 100%, so you will still need to still wear your respirator when prepping. Dust extraction doesn't stop the chips either.

A recirculating extraction system returns filtered,clean air back into the workshop. The filter is sufficient to remove stone dust from the air, including respirable silica (usually a HEPA filter). The system is self-contained. This includes purpose built recirculating extractors as well as shop vacs.

An extraction system that is vented to the atmosphere exhausts the air outside, away from the working area. If dust laden (particularly relevant to air abrasive or grinding applications), the air should be partially cleaned before being ejected using a dust collector or cyclone. This often refers to impellar fans.

CLOSED system Pros & Cons

- Purpose built abrasive vacs or recirculating extractors are often quite quiet to run.

- H- Class vacuums, although the cheaper option, are often very noisy to run.

- Extractors with higher airflows can get expensive.

Must be rated for stone dust for your safety (not only HEPA filtered but also usable with stone dusts)

Must be rated for abrasive dusts for the lifespan of the unit.

- Continuously rated motors are hard to come by. If you do not purchase one with a continously rated motor and intend to work long hours, expect to take frequent, extended breaks or burn out your extractor very quickly.

- Filters need regular cleaning and/or replacing. Bagged units become quite expensive as the bags get filled.

- Only suitable for one workstation at a time.

- Not suitable for extracting 'open air'. Work effectively when extracting a blast cabinet.

Often quite portable so can be moved from workstation to workstation.

Easy to install

OPEN system Pros & Cons

- Fans with impellar blades typically are noisy, but not extremely noisy.

- Cheaper, capable of very high airflows

- Does not need to be rated for certain dust types

Heat loss. In the winter, outside air is pulled in at the same rate as it is ejected from the workshop. This means a warm workshop will quickly become cold.

- Some do not have continuously rated motors, so you will need to investigate this before purchasing.

More difficult and labourious to install, but once installed it is permanent.

Suitable for multi-station workshops.

It may not be appropriate for you to vent the dust outdoors.

CLOSED SYSTEMS

Shop Vacs and Vacuum Cleaners

A vacuum is often the cheapest place to start with dust extraction, but there are a few major disadvantages. In fossil preparation, especially when working with abrasives, we must consider that the dusts are indeed abrasive. No standard, off-the-shelf vacuum that we have found is expecting this level of abuse and so the motors can burn out quite quickly. No warranty that we know of covers this type of usage. They are also not designed for running for long periods of time, and can be extremely noisy. This is a viable option if you don't do too much prepping at a time, don't mind the noise, and can accept that the vac will be somewhat disposable. Shop vacs are only really effective when working inside a blast cabinet or small enclosed space, with the hose fed extremely close to what you are working on. Keeping the hose as short as possible maximises effectiveness.

It is essential to choose the right type of vacuum. In the UK, we classify vacuums into L, M and H class (Low, Medium and High hazard). We would go with an H-Class filtered vacuum. These units are effective and reliable at filtering dust. With any of these vacuums, always make sure you are still wearing a mask whenever in your prep room. Having dust extraction is not a license to not wear a mask.

- These categories don't refer to the amount of dust that they extract, rather the dust that the vacuum can retain.

- H Class traps 99.995% of dust under 1 micron, and is suitable for use with hazardous dusts.

- You can also get MDF dust extractors (make sure it is 0.5 micron filter or less), but with these there is no guarantee that they are up to a certain level of filtration and usually don't meet the requirements to be classified as H- Class. Therefore, we do not recommend these as they have not necessarily passed any standardised tests.

Fine dust can quickly clog the filters of an H- Class vacuum, and so pre-filters and cleaning mechanisms are important features to consider when shopping. You can increase the lifespan of a vacuum by adding in a dust collector or cyclone. This will prevent a lot of the abrasive dust at least getting into the vacuum itself. However, this also decreases the performance. You should also make sure that any air leaks are fully sealed as they will impair the performance. It is necessary to create a vacuum inside the hose.

DO NOT just use a standard, off-the-shelf vacuum if you are looking to protect your health. These will pump the respirable silica back into the room! You may have seen and been tempted by a 'dust and chip' extractor. These are usually quite cheap and readily available from DIY stores. However, they are designed for coarser woodworking dust. They are wholly inappropriate for fossil preparation. They might pick up the messy dust, but they can't retain the very fine, dangerous respirable crystalline silica and that is not what they are designed to do. For those on a very tight budget, these are tempting, but be extremely careful to always wear your dust mask/respirator from the moment you enter the room where you prep. When it comes to your health, you might think'it's better than nothing'. In fact, quite the opposite. 'Nothing' wouldn't forceably pump dangerous dust around your workshop or lull you into a false sense of security.

HPLV (high pressure low volume) dust extractors

We're now going to talk about industrial dust extractors. These work in much the same way as vacuums, operating at higher pressures and so you can feel the suction quite well. These are typically portable and don't take up too much space. They are used in industry for fume extraction and dust extraction of hazardous dusts. We can also use them in our fossil preparation workshops. There are larger, industrial models available for professional and institutional laboratories that require a higher capacity and extraction rate that we will not discuss here.

The one that we recommend is the BOFA DustPRO 400. This has a brushless motor and so is designed for long periods of continuous running, and moves 400m3/hr of air (235 CFM) which for a small extractor is about as good as it gets - considerably more than a vacuum. The operation is reasonably quiet. The HEPA filters take out 99.997% of 0.3 micron particles. When using abrasives or grinding, we always use a dust cyclone or collector inbetween the BOFA and the workspace to protect the filters, and to prevent the bag from getting too full too quickly. These dust extractors are a fantastic option for those who do not have the ability to vent the dust outside, and conform to a number of legal workplace requirements as long as they are properly maintained.

You may have also come across models like the CamVacs which are designed to extract MDF dust. We have been told explicitly by the manufacturer that these are not for anything other than wood dust extraction, and other types of dust are not suited to the filtration and would potentially damage the motors.

VENT-TO-ATMOSPHERE SYSTEMS

HVLP (high volume, low pressure) dust extractors

These are the most common dust extractors found in the home fossil preparation workshop, at least here in the UK. They work at lower pressures, and rely on moving VAST amounts of air out of your workshop. Don't be fooled by the fact it doesn't feel as 'sucky' as a vacuum - these extractors work on moving volumes of air and are extremely effective. These are typically not purchased as such, but in fossil preparation should be used as 'vent-to-atmosphere' extractors. This will most likely take a little modification.

These extractors are usually much more powerful and effective than other types of extraction, and remarkably affordable. They are typically hooked up to ducting and sent to vent outside. Most extractors use a high efficiency impeller fan which gives a very high airflow despite the fact the motor usually runs off a normal household single phase supply (i.e. not industrial 3-phase supply). These extractors are usually found with 100mm ducting - downsizing ducting means downsizing the amount of airflow in the duct at any one time. By reducing airflow you can not only not extract nearly as much as you hoped, but also put excessive strain on the motor of the extractor. Always try to match the size of outlet that your extractor comes with.

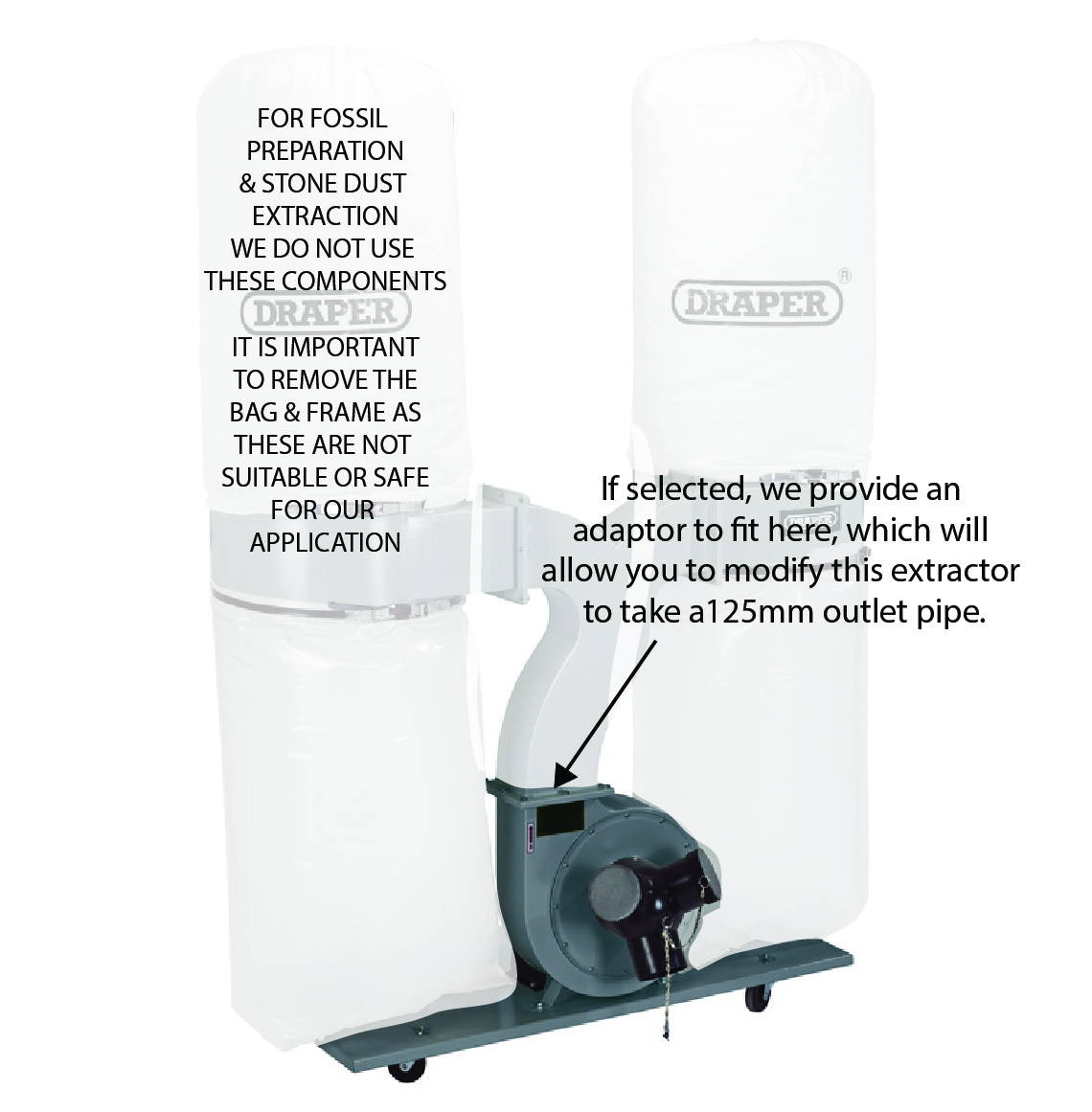

A quick google search of HVLP dust extractors will generate a lot of pictures of huge things with bags. These are completely inappropriate and likely dangerous if used for fossil preparation - the cloth bags are often only rated down to 5 microns, meaning that you are not protected against the most dangerous of the fine dust. The use of this type of extractor might generate a false sense of security and won't benefit you in terms of health in any way. The dust is still present in the room. They help for messy dust, but don't make much difference for the dust that it is essential you extract. These bags are a loose weave to allow a vast amount of air to pass through them (what comes in must go out!).

Some retailers offer a 1 micron cartridge filter (either optional or inclusive) which will be better suited for fine dust. However, a rotating paddle inside the filter is necessary to shake the dust loose so that it doesn't get clogged. By fitting a 1 micron filter bag to a dust extractor, you do reduce the amount of air movement and therefore the power of the extractor. This will in turn damage the motor on top of preventing it from working as it should. There will still be some escape of respirable silica through a 1 micron filter.

These types of extractors do work as closed systems if you fit them with a 0.3 micron HEPA filter (which is typically designed for use with MDF which creates toxic dust in a woodworking environment). These machines are enormous and quite expensive. For instance, at Axminster Tools the cheapest solution that may be suitable (it is designed for woodworking) is nearly £2000 and is 16 Amp designed for trade/business use. If using air abrasives, especially aluminium oxide, will damage the motor in the long run and the whole unit will likely need replacing and so could end up being a very costly approach. You will need to make sure that the bags do not become clogged. These extractors need to be able to vent very efficiently if venting through bags.

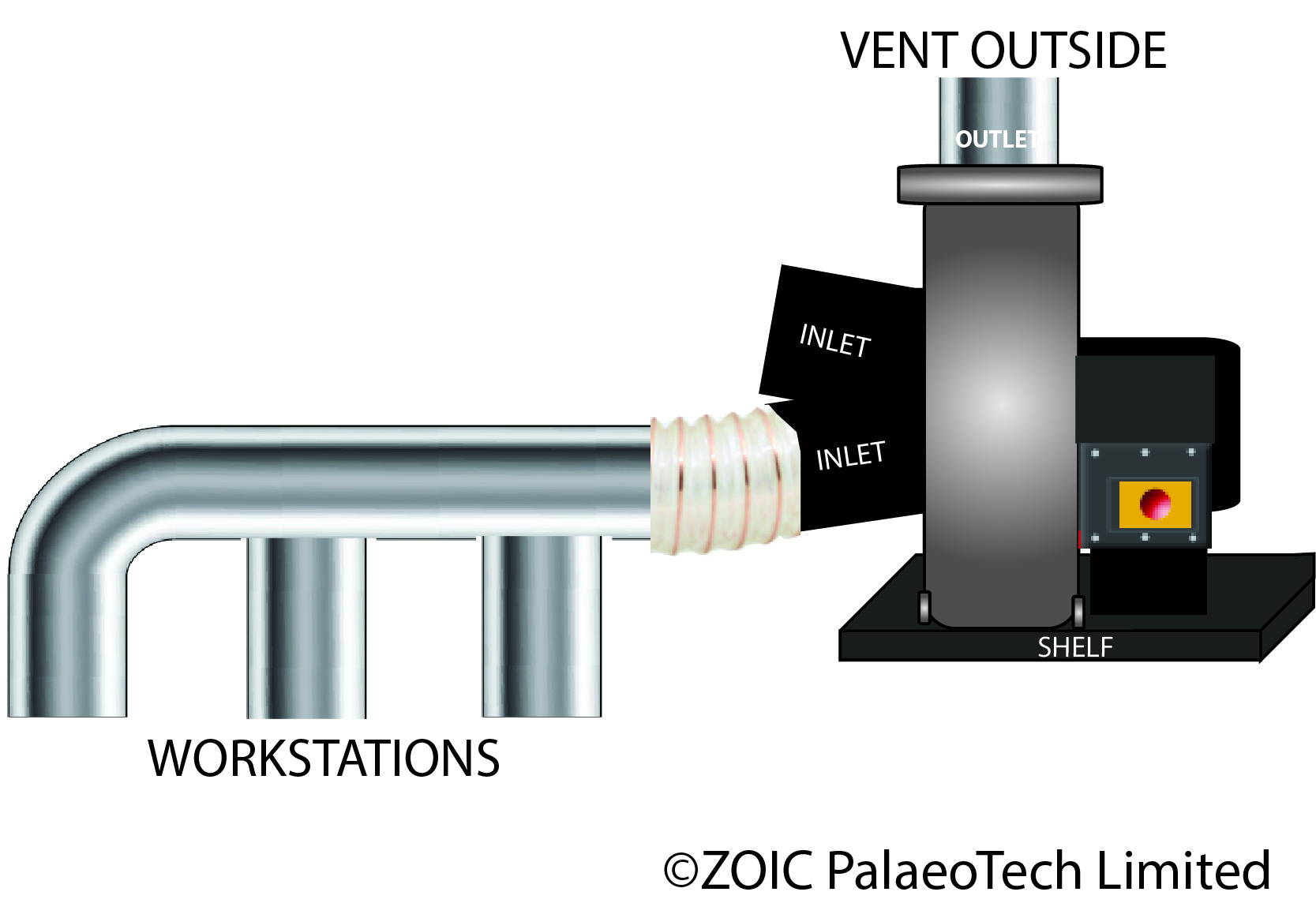

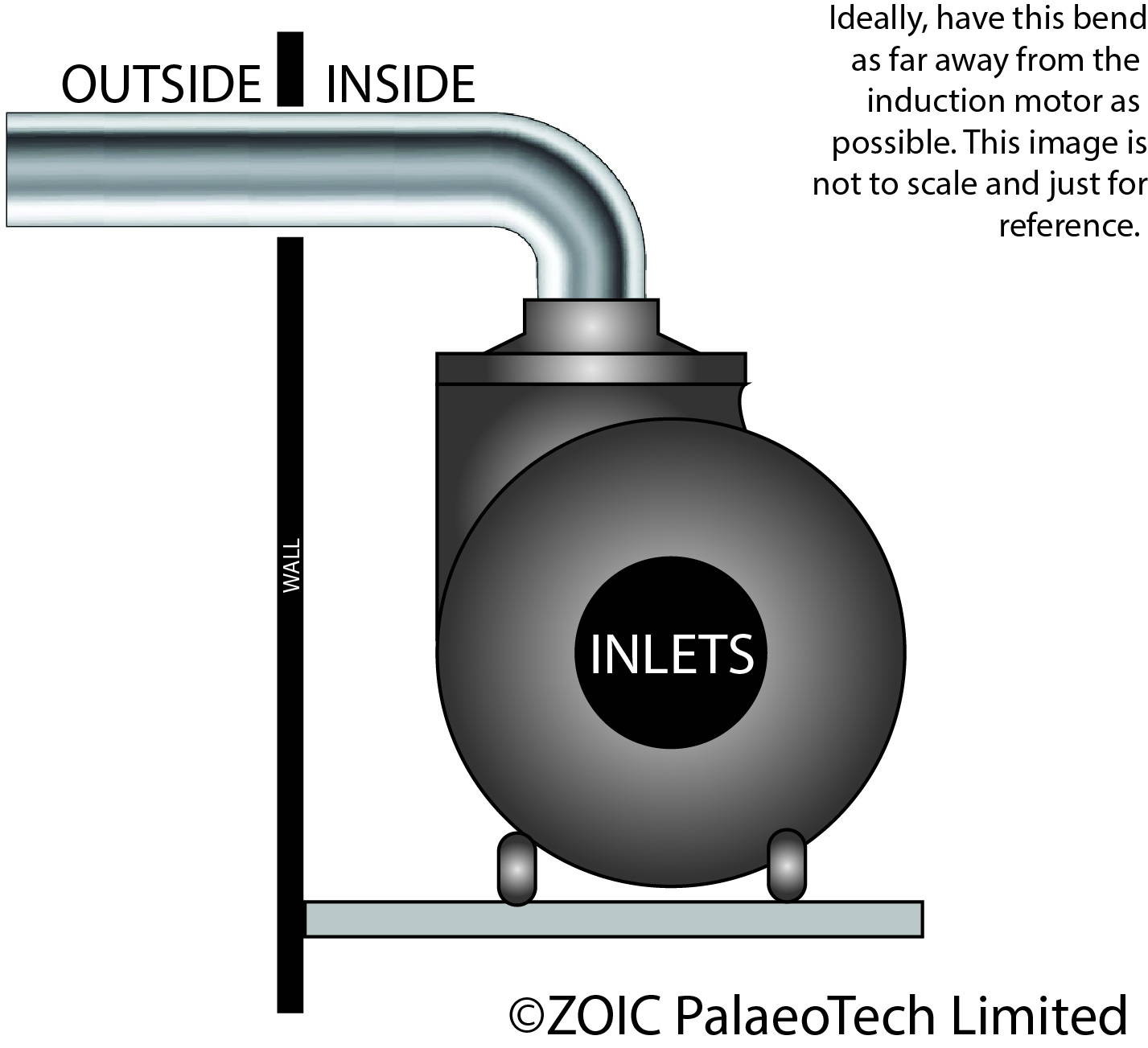

What many people do is take the motor off one of these HVLP extractors, and just use that attached to some ducting (keep reading!). The impeller is the valuable bit of any extractor. This does rely on the ability to vent outside. If you plan on mounting the extractor to the wall, the wall must be structurally capable of holding the extractor. It might be best to build a small shelf - some extractors rely on a certain orientation to prevent excessive wear to the bearings. Ideally, mount the impeller/motor assembly in the orientation it is designed to be in.

Which HVLP extractor is suitable for my home workshop?

Small workshop. Limited amount of ducting

The Clarke CDE35B Mini Dust Extractor is an affordable dust extractor suitable for a small workshop with a limited amount of ducting (up to 3m or 2m with a cyclone) and perhaps one or two workstations (e.g. one air abrasive station, one air scribe station). The flow rate is 850m3/hr (450 CFM). This sounds like a lot, but for a low pressure system, this is an entry-level dust extractor only suited to very small workshops, think small garden shed with no room to swing a cat type of thing.

So, first things first, take off the 5 micron filter/bag which you won't be using (as we have discussed, this will force the most dangerous fine dust around your workshop if used!). You can mount this extractor to the wall (or a shelf/table) and set a duct to vent outside (attaching this to where the bag would be). The Clarke dust extractorsare a low-power, low consumption (750 Watt, 1HP) dust extractor suitable for up to 3m of ducting. Do bear in mind, that if you introduce a cyclone in the system, in order to reduce dust output as well as help save the motor, that the 850m3/hr will drop considerably. This can be partially countered by using less ducting (up to 2m).

We have a variety of 'bundles' available in our online shop (available for England and Wales delivery), which come with all the components you should need for a variety of different workshop configurations, plus instructions on how to assemble and install the bundle.

Medium Sized Workshop

For those with a few metres (up to 7m) of ducting and a cyclone, the 1500W Draper dust extractor is a good option. We would recommend only one workstation is operating at any one time to maintain sufficient velocity to extract respirable silica and the majority of nuisance dust. The airflow is 2520m3/hr or 1483CFM.

The bag comes straight off as not suitable for our application (please see the above discussion on fine dust). If purchased from us, with your permission, we can send these back to Draper for recycling and reuse (sadly this affords us no discounts, but at least it doesn't end up in landfill). We use the 125mm outlet port (air out) to route outside.

The Duty Cycle of the unit is S1 which means it is rated for continuous use. This type of motor runs with a constant load for a long enough duration that it reaches thermal equilibrium. Poor maintenance may affect this. It is best to mount this extractor on a shelf (in the orientation they are designed for use in) as this puts the least strain on the motor bearings. However, it can be hung on the wall if necessary - just be aware that the unit may not last quite as long. Check that your wall is strong enough to take the weight of the extractor. You may wish to mount it on your workbench instead if you have enough space and dont mind the vibration.

Large Workshop with Multiple Workstations (potentially in use simultaneously)

For those of you with a lot of ducting (up to 10m), cyclones and potentially two workstations operating at once, the Draper 2200Wwould be the better choice. This does need to be wired in by an electrician for a 16 amp supply. This powerful motor moves up to 3900m3/hr (2295 CFM). This means you can have multiple stations working at once.

When purchased from us, we are uniquely able to supply you with the fittings required to modify the unit to accept ducting for outside venting.

When using an extractor this powerful, it's important to consider if you are able to make up the air in your workshop. Is it well ventilated? One way to check if you are making up the air appropriately is checking if windows/doors are any harder to open when the extraction is running, or if the extractor is noisier when you have the door shut. A large extractor in a small workshop may require a fan installing to help replace the air removed from the room, or require you to leave the door open.

The ZOIC PalaeoTech workshop - what do we use?

We actually use two separate extractors, one for each side of the room. We use the 1500w Draper for iron powder as it is less powerful. We use the 2200W for white powders (aluminium oxide, dolomite, bicarb). This set up is usually not going to apply to everyone. We have multiple workstations and cabinets, many of which may be used at once when we have guests over. We have multiple metres of ducting with quite a few bends.

The 1500w feeds two workstations, one of which has a highly efficient cyclone. The 2200w feeds three workstations, one of which has a less efficient (cheaper) cyclone. The difference is noticable in terms of powder recovered. Both extractors are housed in a small, watertight (most of the time) shed behind our workshop to reduce noise in the workshop itself. The noise from the extractors is minimal, but the noise of the air amplified by the water butt is significant.

We also have an air purifier with a HEPA filter running 24 hours a day, to pick up any of the dust that manages to escape the extractors.

Some fossil preparators use bathroom extractors as dust control because they are very quiet to run. We do not recommend these as they are not specifically designed for dust, let alone harsh and abrasive dusts. You would be looking for a bathroom extractor that can extract at least 1000m3/hr for a small workshop to maintain the velocity required for extracting silica dust. They are different to HVLP extractors as they run at different pressures. A bathroom extractor must then be used with the ducting size it is designed for (otherwise efficiency will be lost and the motor will be under excessive strain).

Most bathroom extractors capable of extracting such high airflows have ducting diameters of 250mm or more, which is HUGE and considerably more expensive. This also means it won't be possible for you to use a cyclone (unless you're willing to spend a lot of money on an industrial one which will probably be taller than the ceiling of your workshop), which has further implications on how much dust is being vented to the atmosphere.Flexible ducting creates quite a lot of resistance (as it is not smooth on the inside) and so should be avoided as much as possible or kept to a minimum as this will put strain on the motor.

A further feature you would need to consider is that the motor would need to be mounted on the outside of the extractor to prevent abrasive dusts from entering the motor. Any dust filters you see available for bathroom fans are not suitable for our application - they are for collecting household type dust in low volumes. Indeed, many manufacturers will recommend against their use because of the added strain on the motor.

Venting to the Atmosphere - How do I do this safely?

In the UK, the main requirements for venting to atmosphere are: extracted air, whether cleaned or not, must not enter the same building or other buildings until the contaminant has reached negligible concentrations.

We can approach this in two ways:

1. Expel as little dust as possible (i.e. if grinding or using air abrasives that generate a lot of dust, make sure you have a cyclone to collect as much dust as possible). If you are just using air scribes, the chances are the extracted dust could be considered negligible.

2. Do not expel dust where it can enter buildings through vents, windows, air conditioning units, chimneys or other openings.

If you are extracting anything other than stone dust, or the most commonly used air abrasive powders (iron, aluminium oxide, dolomite, sodium bicarb) you will need to investigate any further requirements.

Option 1: Vent dust into airstream via chimney or stack

Send the dust upwards into the atmosphere. The plume will then be carried by the prevailing wind. You want your stack to be a minimum of 2m off the ground, but consider eddies and issues that may arise with surrounding buildings. If you are working in a multi-storey building, get the vent a good height off the ground if you are able to keep it supported against the side of a building.

Be aware of your neighbours and surrounding properties. Just because the prevailing wind carries the dust away from your property, it may blow it onto someone elses if the location of your exhaust is not carefully considered.

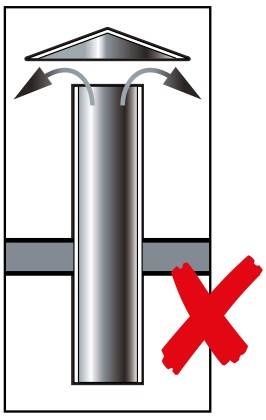

Do not cover the stack with a rain cover or anything that may impede the airflow or force it downwards. However, we would recommend fitting a mesh or boiler flue guard to prevent birds nesting in it.

Source: HSE, 2017. Do not put a raincover on the stack that might force the dust in a downwards direction.

Option 2: Vent dust into a water butt

If you vent into a water butt, make sure that it is partly filled with water, but that the ducting does not extend into the water. The air pushes the dust into the water which captures most of it. The clean air can then escape.

The extraction is at its most effective when the outlet is unimpeded, and placing the duct underwater will not only strain the motor, but prevent the extraction from working almost entirely. You will need to suspend the hose above the water level, and drill some large holes in the top of the water butt to allow the clean air to escape. Again, your extraction will not work correctly if the air cannot escape.

There will inevitably be some dust escape through these exhaust holes. When the water level is checked regularly the problem is reduced, but you may need to construct a baffle wall. This should keep most of the escaped dust contained. You should already be using a cyclone so the dust levels will already be very minimal (we will discuss these next).

Venting into a water butt is the noisiest option as the sound is amplified. A baffle may help reduce noise. You may reduce the noise by wrapping the water butt in acoustic insulation, but ALWAYS make sure there are sufficient outlets for the air to escape.

REDUCING THE AMOUNT OF DUST REACHING YOUR EXTRACTOR

Dust Cyclones

Whether venting to atmosphere or using a recirculating system, we consider a dust cyclone to be essential when working with large volumes of dust or powder. This will apply particularly to those of you using air abrasives, prepping frequently or grinding.

There are a number of advantages to using a dust cyclone or dust collector, which fits inbetween your workstation and your extractor, taking out most of the dust from the airstream before it gets to your extractor.

- Save time and money cleaning or replacing filters on recirculating extractors.

- If using recyclable powders you'll be able to capture these before they are lost (espcially helpful with iron powder as the particles small enough to be captured by the cyclone are no longer suitable for air abrasion at high pressures).

- Zero ongoing maintenance costs (no replaceble/wearing or moving components).

- Helps protect the extractor unit from particularly abrasive dusts and larger particles that might cause damage or sparks.

- Considerably reduce release of dust to the atmosphere (which is a requirement in many countries).

- Save a fortune on bags with recirculating extractors.

- Up to 99% of particles can be collected.

How do dust cyclones work?

A dust cyclone or dust collector is located between your workstation and the extractor. The air enters the cyclone full of dust, and the shape of the cyclone is designed to generate a vortex which forces those particles heavier than air to drop out of the airstream. These particles are spun against the sides of the cyclone, which increases the G-forces, pulling even more particles towards the edge and into the bucket or recepticle below. The clean air continues up and out of the top of the cyclone towards the extractor.

The dust receptacle in the fossil preparation workshop can be a simple lidded bucket. When you see kits from woodworking suppliers, these usually come with HUGE buckets designed for wood dust and chips. Rock dust is considerably heavier and denser, so it's easier for us to manage and takes up less space if we use smaller buckets.

It's also possible to use the same lid and change the buckets when switching between powders. This becomes quite an easy storage solution if you have a variety of buckets.

The cyclone must be sized to the extractor you are using. You can use a very small cyclone with a shop vac, LVHP extractor or vacuum. Larger cyclones are necessary if you have a more powerful extractor and 100mm or 125mm ducting. The cyclones on our website are all rated for different airflows. If you choose a cyclone that is too small for your needs, you will not only reduce significantly the volume extracted, but you could also put excessive strain on the motor of your extractor.

Larger, more efficient cyclones are all cone shaped. This helps vortex formation and produces the most efficient results. There is always a drop in velocity in the system once a cyclone is installed, but the conical cyclones reduce this as much as possible. A cheap alternative if you need a cyclone for 100mm (4") ducting is a bucket with adaptors, a sort of DIY kit. However the velocity drop is much greater with one of these kits and less powder will be collected as they are much less efficient.

Be aware that the presence of a cyclone does not mean that respirable silica will be taken out of the airstream. Cyclones are most effective with coarser dust, and don't do much to filter out the really fine dust (e.g. anything less than a micron).

DUCTING IN THE WORSKHOP - FOR HVLP EXTRACTORS

It is important to choose the correct ducting for the job. Stone dust and abrasive dusts are some of the harshest dusts there are, and so even in the home workshop we need to be conscious of this.

We use galvanised and PU flexible ducting in the fossil preparation workshop rather than plastic, PVC or thin aluminium. This is for two reasons:

1. It is more resistant to wear than plastic,

2. It can be grounded more easily.

Because the minerals within most rocks, as well as abrasive powders, are very abrasive by nature, it is not appropriate to use plastic or thin metal fittings. These will be prone to wearing through quite quickly, particularly on bends and junctions. Galvanised ducting is the most cost effective, wear resistant ducting on the market. Rock chips, stone dust and abrasive dusts are all very likely to wear away any surface, and even the bends of galvanised ducting should be checked for wear periodically. PU flexible ducting is 5x more wear resistant than PVC.

Galvanised ducting and PU flexible ducting with a zinc core are also more easily grounded. This is particularly important when using potentially explosive powders like iron powder. By grounding the ducting, we can reduce the buildup static electricity. A further measure we can take is to include a dust cyclone inline, which will help prevent rock chips reaching the impeller motor, which may cause a spark and ignite the airborne powder.

In fact, most flexible ducting on the market is designed for fume extraction or moisture control, not dust control. Any PVC or plastic fittings will either be designed for domestic or commercial ventilation (such as bathroom fans or air conditioning), or if they are particularly thick they might be designed for wood (or soft) dust extraction. The fossil preparator may be tempted by the cheaper prices on plastic fittings, or even think they have found a 'life hack' by using guttering, but we will stress how important it is to use the correct fittings for the job. In the image below we run through why we might or might not use various ducting.

When installing ducting, we must also consider that what we use and where will impact how well your extractor works and how much strain it is under. You've already worked out how powerful your extractor needs to be to suit your workshop. The more powerful your dust extractor is, the more likely it is you can get away with longer lengths of ducting. To get the most out of any extractor, consider the following points:

- Minimise the number of bends and joins. With each bend, you lose a considerable amount of velocity.

- Minimise the amount of ducting altogether - the less you have, the better your extractor will work. Try to keep it as simple as possible.

- Keep the amount of flexible ducting to a minimum. The inside of flexible ducting is ridged, like the outside. Galvanised spiral ducting is smooth on the inside, which helps maintain the airflow at the higher speeds required and increases the overall performance.

- Use flexible ducting wherever flexibility might be needed (e.g. on a cyclone, on the back of a blast cabinet, attatched to a captor hood). Elsewhere, in fixed positions, try to use elbows and bends as this will maintain the airflow.

- If you have more than one run to a workstation, use a blast gate on each run.

- You can purchase attenuators to reduce the noise that comes through the ducting from your extractor. In most circumstances, these are not necessary as that noise is usually outdone by the noise of your tools.

Where do I install my ducting?

This is entirely up to you! Wherever it is most convenient. If you are using blast gates, these will need to be accessible. You will also need to have the on/off switch on your extractor accessible unless you have it rewired to a switch.

The most popular approach is installing the ducting high up on the wall (using wall mounting brackets) where it takes up the least workbench space. Each workstation then has a branch of ducting come down to it.

If you are trying to minimise the length of ducting, you might consider having the ducting mounted lower down the wall or even at the back of the workbench if you have space. This is where we put ours as we like to have fossily artwork on the walls of our workshop.

We provide here a quick guide to how our range of galvanised and flexible ducting fits together (this likely does not apply for any other ranges so please do your research before purchasing!). As anyone who has installed ducting before will know, it's really difficult to work out which parts belong with which (ask us how we know!).

CAPTOR HOODS & BLAST CABINETS

Air Abrasives & Grinding

When using air abrasives or grinders, the volume of dust produced is enormous. It is therefore essential to work inside a blast cabinet. A blast cabinet is a fully enclosed space, that usually has arm holes with gloves or sleeves that you put your hands into. The blast cabinet is hooked up to dust extraction. Using a blast cabinet reduces the amount of space that your extractor has to extract, and is therefore much more likely to pick up significantly more of the dust cloud.

The blast cabinet must have sufficient surface area that is not enclosed to allow a constant flow of air from the room, into the cabinet and towards the extractor. You must be able to replace the air that is being removed.

For most cabinet designs in fossil preparation, the arm holes are sufficient. When the extractor is on, a 'negative pressure chamber' is created, where the pressure in the cabinet is slightly lower than atmospheric air pressure. This means that dust cannot get out, and can only be extracted away as the path of least resistance is from the "high" atmospheric pressure to the "low" cabinet pressure.

Remember that not all of the dust will be extracted, and some will remain in the cabinet, this will be especially evident on the walls and cover as a thin layer of electrostatically clingy film. Therefore it is still important to wear a respirator or dust mask even if you work using dust extraction and a blast cabinet.

Air scribes

Air scribes don't create as much dust as other methods in fossil preparation. Therefore, the majority of people don't use a blast cabinet unless they wish to control nuisance dust and rock chips. However, extraction is very much advisable to reduce the quantity of respirable silica in the air to negligible levels.

If you are extracting an open workbench, you will find that there is little to no point if you aren't channeling the dust where you want it to go. We use captor hoods to direct the dust. These help direct the flow of air and reduce eddies. However, these are only effective if you ensure that the hood is always as close as possible to the workspace and is moved to follow the work.

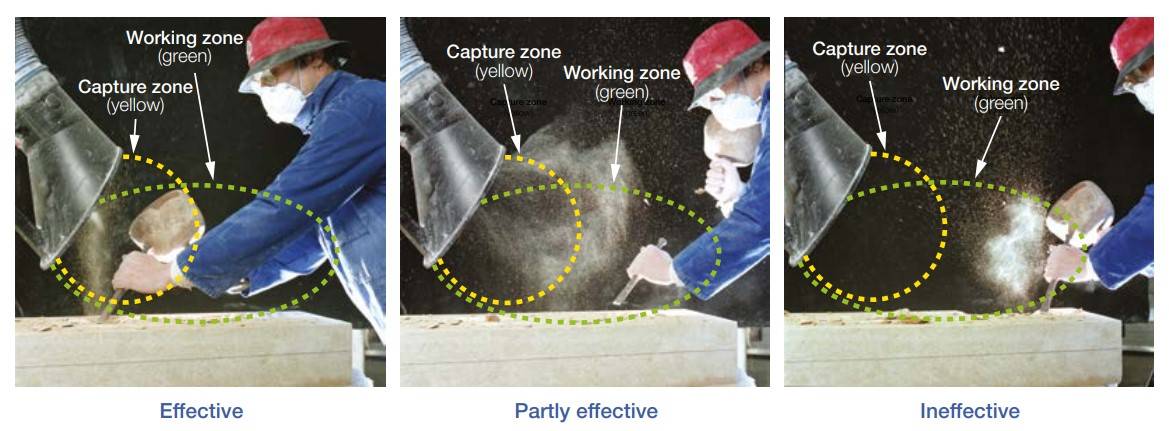

This diagram shows the variation in effectiveness depending on how close you are working to the captor hood. It is necessary to be very close to the captor hood for it to be effective. HSE, 2017. From "Controlling airborne contaminants at work. A guide to local exhaust ventilation (LEV)".

Although it looks as though the work is close to the captor hood, it's actually too far away for it to be performing effectively. The fossil and the captor hood need to be moved closer to one another. The man in the photo should also be wearing a respirator. Dust extraction helps, but is still not 100% effective. Thank you Chris for posing!

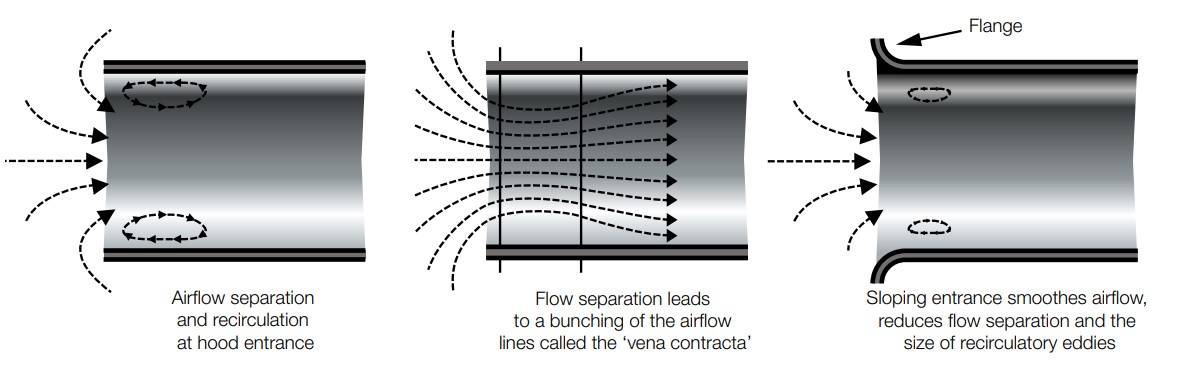

This diagram shows why it is essential to have a slight 'flange' on the captor hood. If you are just using a tube of flexible ducting, this will cause eddies and flow separation, reducing the effectiveness of the dust extraction. HSE, 2017. From "Controlling airborne contaminants at work. A guide to local exhaust ventilation (LEV)"

Put into practice in the fossil prep workshop, installing a captor hood will greatly increase the effectiveness of your extraction. The flange doesn't have to be a set circular shape, it just needs to be more 'funnel' shaped than a straight piece of ducting.

When working with larger fossils, a flexible arm with a captor hood can be a brilliant option for dust control. A flexible arm is an adjustable piece of ducting that can be manoeuvred quite easily from above. Therefore, no part of it needs to be resting on the specimen if it is delicate. Most of the ones available on the market are for fume control and so not suitable for dust extraction. We use an extraction arm with a 1m radius and another with a2m radiusin our workshop. (Yes, this photo was staged with one of Craig Chiver's wonderful ichthyosaur replicas as an example!).

If you can see the Geological time chart in the picture on the left, this was gifted to us by a lovely fellow fossil prepper. Thank you!

Another tip for those of you with workbenches and 'open' extraction, is that you can filter the air a little with a very cheap and easy tip. If you purchase a pair of 15 denier ladies tights or hoisery, you can stretch these over the captor hood. This will prevent small chips and bits of rock being sucked up and into the extraction. If you're prepping something very fragile, this might save the odd bit that flies off!

Maintenance

It is important to keep a close eye on your dust extraction systems and to keep them well maintained. Of course, read the instruction manual and perform all maintenance checks and duties as specified by the manufacturer, but we can offer some general pieces of advice also:

Clean down equipment before starting maintenance using a damp duster or another dustless method.

Looks for signs of damage daily. Noisy or vibrating fans can indicate a problem.

If in doubt, enlist the help of a ventilation engineer. This is a legal necessity every 14 months for an employer in the UK, but the option is very much there if you are a hobbyist.

Make sure you can get spares easily. Is the manufacturer a respectable brand that consider longevity of their products important?

For filtered units:

Clean air filters daily or follow the manufacturers advice

Shake down air filters regularly (e.g. every hour)

Check that the filter seatings are in good condition

Check the HEPA filters as necessary.

Advice for international customers when purchasing dust extraction

There will be a lot of you reading this who will have to do your own research into products, as we are unable to ship beyond mainland UK with many of our extractors.

When looking to purchase dust extraction, ask a few key questions. We have spent a long time searching for suitable dust extraction solutions and if there's one thing that is clear it's this: companies that sell dust extractors designed for woodworking really want to sell you something. We see it as our responsibility to only supply decent products that are suitable to fossil preparation, but we have learnt over the years when investigating products that there are a lot of salespeople who are willing to 'bend the truth' or exaggerate to make a sale.

If you explain you are using the extractor for stone dust, and the company doesn't seem to care or says 'oh yes it will do that', they likely don't understand the risks. We have had discussions with major manufacturers and their technical departments (we won't name names), who have gladly told us that their extractor is effective with stone dust. It is clear that many woodworking companies in particular do not understand what respirable silica is or that it is a hazard. We have been recommended models that filter down to 5 or 10 microns which as we have discussed is completetly inappropriate. Because what we do is quite niche, we do need our buyer beware hats on! Be aware of the risks, be aware of the types of extractors that might work, and go from there. Don't wildly trust a salesman or even technical person as it's your health potentially at risk.

Most companies who supply woodworkers or general extractors will not back up their warranty if the extractor is used with abrasive powders. This does limit the selection. Make sure to ask about filtration levels (HEPA required in a recirculating system), the motor rating (how long can it be used for continuously?), airflow, etc.

This article does not represent any legal or legally binding advice. We are not LEV experts, but we hope we have compiled some interesting information for your consideration. This free and non-exhaustive article exists to introduce you briefly to the risks, and introduce you to some of the control measures that you can undertake in your workspace. It is up to you as an individual to research further to fully understand your risks and to lessen them as much as possible. If you are an employer, it is vital that you are aware of and follow the legislation in your country/state/region. We will link below a number of free, governmental resources from the USA and UK concerning construction work and stone dust.

Health & Safety Executive UK - Local Exhaust Ventilation